Description

Antistatic finish

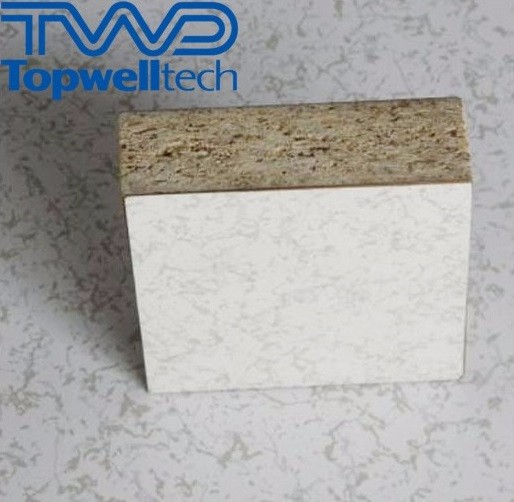

High Pressure Lamination

HPL is considered to be one of the most durable decorative surface material and is available with special performance properties including chemical, fire and wear resistance. HPL is produced by saturating multiple layers of Kraft paper with phenolicresin.A layer of printed decor paper is placed on top of the Kraft paper before pressing. The result sandwich is fused together under heat and pressure (more than 1,000 PSI).Because phenolic and melamine resins are thermoset plastics,the curing process transforms the resin into plastic by a cross inking process that converts the paper sheets into a single, rigid laminated sheet. Thermosetting creates strong, irreversible bonds that contribute to HPL's durability.

Test Properties

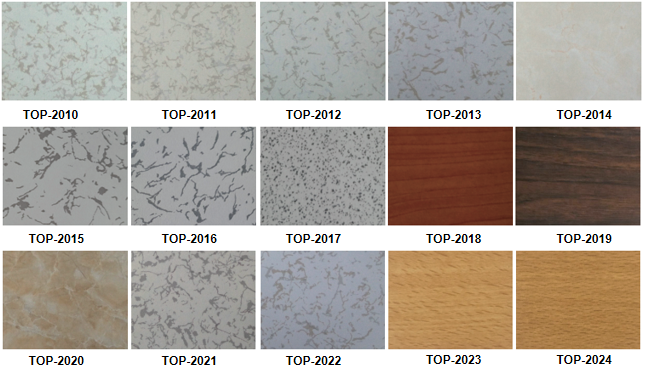

Color pattern & Surface Finish : No significant difference between the corresponding

color reference sample and master ;

Surface Defects : No Spot , dirt and similar surface defects ;

Edge Defects : No Visual defects can be present on all four edge of Laminate ;

Sanding Defects : Slighter Chatter marks allowed ;

Resistance to Surface Wear : AC3, Greater than or equal to 2000 cycles ;

Thickness : +_ 0.10 mm ;

Flatness : Less than mm 60mm ;

Resistance to Scratching : Greater than or equal to 3.0 N ;

Resistance to Steam : Rating 4. Slight change of gloss/color only visible at

certain viewing angles ;

Resistance to staining : Min rating for group 1 & 2 : Class 5 ( No visible change)

Min rating for group 3: Class 4

English

English Spanish

Spanish Russian

Russian Arabic

Arabic Français

Français